Smart Manufacturing

Analysis and optimisation of production machinery and processes

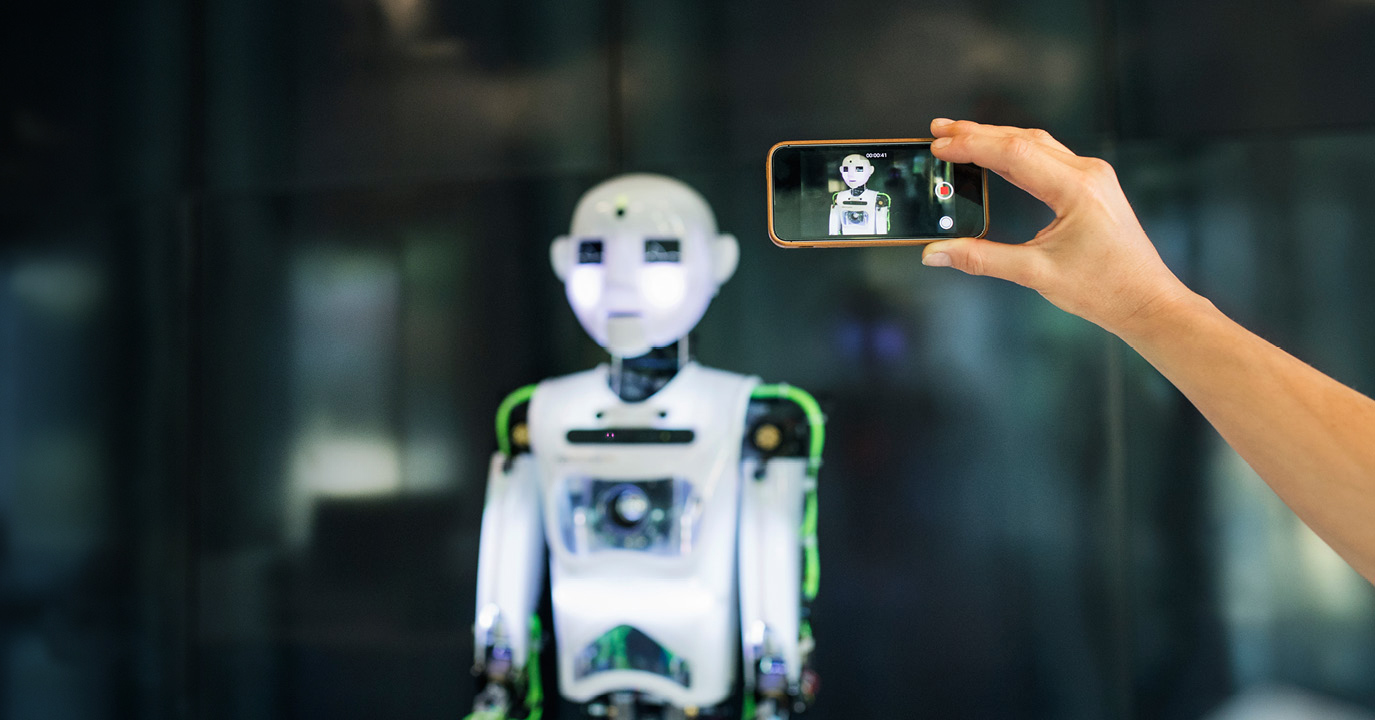

Smart Manufacturing is the future of industrial production. On its way there, the established concepts of the Industry 4.0 framework are used. With the Internet of Things, artificial intelligence, mobile devices, automation technologies and data-driven control models, a great number of production processes is redefined, allowing for gains in efficiency which have been inconceivable so far. In a nutshell: Your production lines will transform into networked and self-optimising units.

At the same time though, you’ll be facing increasing requirements with regard to the integration of production and business processes. In order to actively shape this transformation, you have to master the whole transition process – from the design to the successful transformation of processes and IT systems. This is where our major focus lies. We design and manage your transformation projects true to our motto “Excellence in Transformation”. In this process we operate independently of our own implementation interests. This makes us 100% free to concentrate on your requirements and manage your project service providers from a neutral point of view.

Benefit from our comprehensive wealth of experience in the fields of production, business processes and IT! Together with you, we shape a production landscape that is just as smart as your products

As a starting point, an assessment of Industry 4.0 maturity will be carried out in your company. To do so, we rely on the established ACATECH framework for Industry 4.0, which has been developed by the National Academy of Science and Engineering.

Taking this as a basis, we draw up a master plan together with you, which will contain all facets required for preparing your production and logistics processes optimally for the future – focussing on efficiency, the enhancement of transparency and the achievement of sustainability targets or quality objectives.

This will be our foundation for designing and managing your transformation projects, supporting you with technical IT and production experts, and guiding the changes that will be taking place in your production environment.

Make use of our expertise to put the contents of your Industry 4.0 master plan into practice.

Your benefits at a glance:

We analyse your production data to increase your production efficiency.

Our failure analysis minimises your downtimes and improves the product quality.

With our spare parts management analyses you optimise costs and logistics.

Our energy management analyses provide you with a further component for sustainable production.

The decade-long experience and professional achievements of our consultants speak for themselves. We jointly assist you in establishing a data-driven production landscape which will make your production processes smarter, more efficient and more cost-effective.

We utilise tried and tested analyses and the proficiency of state-of-the-art production technologies to optimise your shop floor by means of intelligent networking and real time data. In this way, you achieve enhanced transparency and increased efficiency at the production level.

In the field of maintenance we utilise predictive analyses in order to minimise costs and downtimes as well as shape maintenance processes in a proactive fashion.

We optimise your quality management by carrying out automated, AI-assisted quality analyses that ensure continuous compliance with and improvement of your quality standards.

With our spare parts management analyses you minimise downtimes and reduce cost of storage and logistics.

The use of solid energy management data reduces your consumption and promotes sustainable production.

Rely on data that will revolutionise your production! We stand for intelligent production that saves costs and enhances your competitive ability.

With our prototypes for analysis, quality control and the control of production machines we prevent data loss and establish a seamless analysis and control system.

In our feasibility studies we jointly check the technical implementability of potential approaches for eliminating the data gaps.

We develop hardware and software solutions in the form of Minimum Viable Products (MVPs), by means of which you analyse and control you production machines more efficiently.

Our go live support will help you and your service providers integrate the proven digital prototypes quickly and efficiently into your production process.

Our digital machine services will make your production landscape smarter and future-proof. Utilise our expertise to establish a consistently data-driven production environment!

Therefore we revolutionise the handling of your production expertise. We use advanced AI technologies to digitise your expertise and make the professional expertise from individual employees easily accessible to all employees in the company.

We integrate this digital expertise directly into the control processes of your machines and in this way enhance your efficiency and quality of your production.

In joint collaboration with you, we then develop customised digital wizards by means of which your employees can retrieve this expertise in real time and are able to solve everyday tasks more quickly and more accurately.

Rely on our expertise when it comes to digitising your expertise! Together with us you transform your production knowledge into valuable digital assets.

A process architecture that fully integrates your business and production processes and allows for data-driven control is the starting point for this.

With a modern data architecture, we lay the foundation for efficient production control based on sensor data and data analytics.

The system architecture ensures the seamless integration of a large variety of IT systems from production control to PLM and ERP systems, including the MES.

Furthermore, our experts develop a modern and customised interface architecture, in order to fully integrate the large variety of mobile devices, sensors, control elements and pre-systems into the production control.

Our architectural expertise enables you to integrate your IT and production processes into your business workflows and to optimise both of the two – in a scalable and resilient fashion.

We plan and manage your transformation projects. In doing this, we always operate independently of our own implementation interests. In this way, we are 100% free to concentrate on your requirements and select and manage your project service providers from a neutral point of view.

We ensure a seamless connection between your business and production processes to allow for efficient and data-driven production.

We plan, implement and integrate your ERP, MES, MDM and PLM systems, in a fashion that is geared to your operative production control.

We create and build scalable and future-proof IT architectures that integrate business workflows and production processes seamlessly.

We stand for the successful flow and completion of your transformation projects. “Excellence in Transformation” is our motto. Let us build the future of smart manufacturing together!

Success Stories

Impact of Digitalization

Analysis of the impact of digitalization on the business model, development of scenarios to adapt/realign individual business areas, derivation of scenarios for the required IT budgetsDigitisation in Enterprise Content Management (ECM) Area

Digitisation of complete company document workflows, ECM design, the definition of Enterprise Architecture, implementation supportIndustry 4.0 Assessment

Assessment and optimization of production with a focus on consistency of planning and data models and traceability in the production process.

Digital shop floor management

Digital shop floor management through the integration of data from accounting, human resources, machines and logistics into one real-time management system.Sensor system, process control and SAP

Analysis and optimisation of the processes for beverage production, bottling and logistics; connection of the plant sensor system, process control and SAPProduction Optimisation

Optimization of throughput times and reduction of rejects and shortages from planning via BOM to to delivery.Optimisation of production control

IT-based support of the international EPC value-added chain, architecture and international roll-out of the core applications (CAX, PLM, SAP)Cross-plant production planning

Establishment of cross-plant production planning, roll-out PPM and standardisation of the planning and procurement processesOptimisation of production control

System standardisation focussing on the usability in foreign companies and reorganisation of the CAX and PLM control, procurement and manufacturingAI-supported quality assurance

Design and implementation of an AI-assisted, high-resolution image system for automatic quality assurance for the special cables mountedPlant structure planning

Plant structure planning for a new production site and support in the implementation and optimisation of existing production processes.Global MES platform and PLM roll-out

Global standardisation of the shop floor systems for the integrated utilisation and production planning, expansion of the global MES platform and global PLM roll-outEarly-stage error detection and prediction

Analysis of machine data for digital “fingerprints” per machine, derivation of measures for early-stage error detection and prediction.PPS audit and optimisation

PPS audit – Optimisation of the order processing and introduction of supplementary Advanced Planning and Scheduling systems (APS).Optimisation of maintenance processes

Optimization of the value-added structures of maintenance in the location network of a locomotive maintenance companyIT Servicemanagement

Einführung eines IT-Service-Managements inkl. der Automatisierung und serviceorientierte Neuaufstellung der IT-Organisation: Aufbau eines ISO 20000- Qualitätsmanagementsystems; Aufbau eines IT-Security und IT-Service Continuity Managements.Industry 4.0 platforms

Assessment und Optimierung der Produktion mit Focus auf Durchgängigkeit von Planung und Datenmodellen und Rückverfolgbar-keit im Produktionsprozess

Optimisation of global cyber security

Assessment, design and program management of a global program for cyber security in production.